(→Pasteurizing water in a solar cooker: Arranged pics into gallery & added Dr. Jagadeesh's solar water heater jar) |

|||

| Line 37: | Line 37: | ||

[[Image:Wapi-before-after.jpg|thumb|left|200px|Solar Cookers International's [[WAPI]] shown in the solid wax state (left) and liquid wax state (right)]]Since thermometers are not accessible to many people around the world, there is a need for a simple device that indicates when water has reached pasteurization temperatures. [[Fred Barrett]], who was with the United States Department of Agriculture when Dr. Metcalf worked with him on a solar box cooker project in Sierra Leone in 1989, came up with the idea of using vegetable wax, with a melting point near 70°C (158°F), as an indicator. He built several models based on the idea of wax inside a plastic cylinder, and successfully used them to verify pasteurization conditions of contaminated water. In 1992, [[Dale Andreatta]] -- a Ph.D. candidate in mechanical engineering at the University of California, Berkeley at the time -- created the [[Water pasteurization indicator]] (WAPI) in its current form. The WAPI is a clear plastic tube partially filled with a soybean wax that melts at about 70°C (158°F). With the solid wax at the top end of the tube, the WAPI is placed in the bottom of a black container of water that is solar heated. If the wax melts and falls to the bottom of the tube, it ensures that water pasteurization conditions have been reached. The WAPI has a stainless steel washer around it to keep it at the bottom of the container, which is the coolest location when solar heating water.[[Image:Flow-through pasteurizer schematic.gif|thumb|right|270px|An automotive thermostat can be used to control the flow of water through a [[Flow-through water pasteurization device]].]]Since top water temperatures are often 2-5°C hotter than bottom water temperatures, lower WAPI placement helps to further insure that pasteurization conditions have been achieved. |

[[Image:Wapi-before-after.jpg|thumb|left|200px|Solar Cookers International's [[WAPI]] shown in the solid wax state (left) and liquid wax state (right)]]Since thermometers are not accessible to many people around the world, there is a need for a simple device that indicates when water has reached pasteurization temperatures. [[Fred Barrett]], who was with the United States Department of Agriculture when Dr. Metcalf worked with him on a solar box cooker project in Sierra Leone in 1989, came up with the idea of using vegetable wax, with a melting point near 70°C (158°F), as an indicator. He built several models based on the idea of wax inside a plastic cylinder, and successfully used them to verify pasteurization conditions of contaminated water. In 1992, [[Dale Andreatta]] -- a Ph.D. candidate in mechanical engineering at the University of California, Berkeley at the time -- created the [[Water pasteurization indicator]] (WAPI) in its current form. The WAPI is a clear plastic tube partially filled with a soybean wax that melts at about 70°C (158°F). With the solid wax at the top end of the tube, the WAPI is placed in the bottom of a black container of water that is solar heated. If the wax melts and falls to the bottom of the tube, it ensures that water pasteurization conditions have been reached. The WAPI has a stainless steel washer around it to keep it at the bottom of the container, which is the coolest location when solar heating water.[[Image:Flow-through pasteurizer schematic.gif|thumb|right|270px|An automotive thermostat can be used to control the flow of water through a [[Flow-through water pasteurization device]].]]Since top water temperatures are often 2-5°C hotter than bottom water temperatures, lower WAPI placement helps to further insure that pasteurization conditions have been achieved. |

||

| − | [[Image:WAPI in use.jpg|thumb|right|200px|Meatu resident Boniphace Luhende demonstrates solar water pasteurization using a CooKit and WAPI]]During numerous trips to developing countries, Dr. Metcalf has had the opportunity to conduct numerous solar water pasteurization experiments. In Meatu district, Shinyanga region, [[Tanzania]], water most often comes from open holes dug in the sand of dry riverbeds, and it is invariably contaminated. Indeed, the water that was provided in Dr. Metcalf's guesthouse was heavily contaminated. Bacteriological tests of the water during solar pasteurization repeatedly showed indicator bacteria (key bacteria whose presence indicates faecal contamination) becoming inactivated at temperatures just below 60°C (140°F). During all of Dr. Metcalf's fieldwork, he has heated his own drinking water in a solar cooker using a WAPI as a temperature indicator and he has had no intestinal problems. |

+ | [[Image:WAPI in use.jpg|thumb|right|200px|Meatu resident Boniphace Luhende demonstrates solar water pasteurization using a CooKit and WAPI]]During numerous trips to developing countries, Dr. Metcalf has had the opportunity to conduct numerous solar water pasteurization experiments. In Meatu district, Shinyanga region, [[Tanzania]], water most often comes from open holes dug in the sand of dry riverbeds, and it is invariably contaminated. Indeed, the water that was provided in Dr. Metcalf's guesthouse was heavily contaminated. Bacteriological tests of the water during solar pasteurization repeatedly showed indicator bacteria (key bacteria whose presence indicates faecal contamination) becoming inactivated at temperatures just below 60°C (140°F). During all of Dr. Metcalf's fieldwork, he has heated his own drinking water in a solar cooker using a WAPI as a temperature indicator and he has had no intestinal problems.{{Clr}} |

==Pasteurizing water in a solar cooker== |

==Pasteurizing water in a solar cooker== |

||

Revision as of 18:04, 7 January 2010

Water sources, such as that of Mwamongu Village,Tanzania, may be contaminated

A good introduction to solar water pasteurization and food safety is this interview with microbiologist and SCI-founder Dr. Bob Metcalf.

Millions of people become sick each year from drinking contaminated water. Children are especially susceptible. An estimated 1.5 billion cases of diarrhea occur each year, resulting in the death of nearly 2 million children. Worldwide, about 1.3 billion people do not have access to safe drinking water, including nearly half the population of sub-Saharan Africa. Yet, in many of the most severely affected regions, sunshine is an abundant source of energy that can not only cook food but can also heat water to temperatures that kill harmful microbes, making water safe to drink. This procedure is called solar water pasteurization.

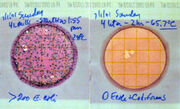

E. coli bacteria (left plate) thrive in water sources, but are easily killed through solar water pasteurization (right plate)

It has been known since the late 1880s, when Louis Pasteur conducted groundbreaking research on bacteria, that heat can kill pathogenic (disease-causing) microbes. Most people know contaminated water can be made safe by boiling. What is not well known is that contaminated water can be pasteurized at temperatures well below boiling, as can milk, which is commonly pasteurized at 71°C (160°F) for 15 seconds.

The chart below indicates the temperatures at which the most common waterborne pathogens are rapidly killed, thus resulting in at least 90 percent of the microbes becoming inactivated in one minute at the given temperature. (The 90 percent reduction is an indicator frequently used to express the heat sensitivity of various microbes.) Thus, five minutes at this temperature would cause at least a 99.999 percent (5 log) reduction in viable microbes capable of causing disease.

| Microbe | Killed Rapidly At |

| Worms, Protozoa cysts (Giardia, Cryptosporidium, Entamoeba) | 55°C (131°F) |

| Bacteria (V. cholerae, E. coli, Shigella, Salmonella typhi), Rotavirus | 60°C (140°F) |

| Hepatitis A virus | 65°C (149°F) |

| (Significant inactivation of these microbes actually starts at about 5°C (9°F) below these temperatures, although it may take a couple of minutes at the lower temperature to obtain 90 percent inactivation.) | |

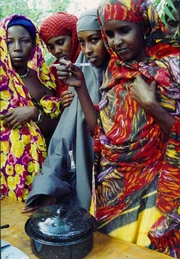

Solar water pasteurization

Solar cooks know how easy it is to heat foods in a solar cooker to temperatures well above 60°C (140°F). Knowing this, Dr. Bob Metcalf and a graduate student of his in the early 1980s, David Ciochetti, studied solar water pasteurization for the latter's master's thesis. They found that when contaminated water was heated in a black jar in a solar box cooker, both bacteria and rotaviruses -- the main cause of severe diarrhea in children -- were inactivated by 60°C (140°F). In the paper published this work (Applied and Environmental Microbiology, Vol. 47:223-228, 1984) it was concluded that if contaminated water were heated to 65°C (149°F), all pathogenic microbes would be inactivated. This includes the hepatitis A virus, which has a 90 percent reduction after two minutes at 60°C (140°F).

Another student, Negar Safapour, found contaminated water could be pasteurized in a black metal or glass container in a CooKit (Solar Cookers International's simple solar cooker) without using the clear plastic bag that is required for cooking. In our experiments it took about three minutes for each 1°C increase from 55°C to 65°C when heating 2 liters of water, and four to five minutes for each 1°C increase when heating 4 liters. Thus, water is at lethal temperatures for several minutes as it is solar heated to 65°C (149°F), and it remains in the lethal zone for many more minutes as the water slowly cools back down to 55°C (131°F).

Solar Cookers International's WAPI shown in the solid wax state (left) and liquid wax state (right)

Since thermometers are not accessible to many people around the world, there is a need for a simple device that indicates when water has reached pasteurization temperatures. Fred Barrett, who was with the United States Department of Agriculture when Dr. Metcalf worked with him on a solar box cooker project in Sierra Leone in 1989, came up with the idea of using vegetable wax, with a melting point near 70°C (158°F), as an indicator. He built several models based on the idea of wax inside a plastic cylinder, and successfully used them to verify pasteurization conditions of contaminated water. In 1992, Dale Andreatta -- a Ph.D. candidate in mechanical engineering at the University of California, Berkeley at the time -- created the Water pasteurization indicator (WAPI) in its current form. The WAPI is a clear plastic tube partially filled with a soybean wax that melts at about 70°C (158°F). With the solid wax at the top end of the tube, the WAPI is placed in the bottom of a black container of water that is solar heated. If the wax melts and falls to the bottom of the tube, it ensures that water pasteurization conditions have been reached. The WAPI has a stainless steel washer around it to keep it at the bottom of the container, which is the coolest location when solar heating water.

An automotive thermostat can be used to control the flow of water through a Flow-through water pasteurization device.

Since top water temperatures are often 2-5°C hotter than bottom water temperatures, lower WAPI placement helps to further insure that pasteurization conditions have been achieved.

Meatu resident Boniphace Luhende demonstrates solar water pasteurization using a CooKit and WAPI

During numerous trips to developing countries, Dr. Metcalf has had the opportunity to conduct numerous solar water pasteurization experiments. In Meatu district, Shinyanga region, Tanzania, water most often comes from open holes dug in the sand of dry riverbeds, and it is invariably contaminated. Indeed, the water that was provided in Dr. Metcalf's guesthouse was heavily contaminated. Bacteriological tests of the water during solar pasteurization repeatedly showed indicator bacteria (key bacteria whose presence indicates faecal contamination) becoming inactivated at temperatures just below 60°C (140°F). During all of Dr. Metcalf's fieldwork, he has heated his own drinking water in a solar cooker using a WAPI as a temperature indicator and he has had no intestinal problems.

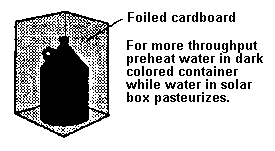

Pasteurizing water in a solar cooker

A standard solar cooker can be used to pasteurize water by simply replacing the food to be cooked with the water to be heated.

Other simple solar pasteurization devices

Portable water testing kit available

Portable Microbiology Laboratory water testing kit contains these individual components.

Dr. Bob Metcalf, a microbiology professor at California State University at Sacramento has prepared a portable water testing kit. Contact information for Dr. Metcalf can be found on his biography page.

See also: Portable Microbiology Laboratory

News and Recent Developments

- November 2007: Solar Cookers International (SCI) will undertake a two-year pilot project to increase water quality awareness and introduce the Portable Microbiology Laboratory and the Safe Water Package to communities in western Kenya. The effort will be led by SCI founder and board member Dr. Bob Metcalf, professor of Biological Sciences at California State University, Sacramento. (More information.)

Frequently-asked questions

How is pasteurization accomplished?

Traditional fuels can be used to pasteurize water, but on sunny days solar energy can be used as well. Simple solar cookers can pasteurize water for a family at a rate of about one liter per hour. Solar Cookers International's reusable water pasteurization indicator (WAPI) can be used to determine when water heated by solar or conventional means has been heated to a high enough temperature to make it safe.

Don’t you need to boil water for 20 minutes to sterilize it and make it safe to drink?

No, it is only necessary to heat water to 65° C to pasteurize it.

What is the difference between sterilization and pasteurization?

Sterilization kills all of the organisms in the water, while pasteurization kills only those organisms that can cause harm to humans.

What common disease organisms are killed by pasteurizing water?

Giardia, cryptosporidium, entamoeba, the eggs of worms, cholera, shigella, salmonella bacteria and those that cause typhoid, the enterotoxogenic strains of E. Coli, Hepatitis A, and also rotavirus which is a major cause of disease in children are all killed or inactivated at 65°C.

How can water be tested in the field?

At Dadaab Refugee Camp, Kenya, villagers check the WAPI

To test whether water has been heated enough to make it safe to drink you can use a thermometer or a water pasteurization indicator.

To test a water source for human or animal fecal contamination, it is best to test for the bacterium Escherichia coli, which is always present in human faeces at a level of about one hundred million E. coli per gram. The presence of E. coli in water indicates recent fecal pollution and a public health threat. Water containing one E. coli per milliliter is considered heavily contaminated. In order to do world-class microbiology in developing countries where there is no lab, since 2000 SCI has used two complementary tests extensively.

The first test is a presence/absence test using Colilert, the most widely used test in the water industry (IDEXX Laboratories, Westbrook, Maine). SCI uses the Colilert MPN tube, which is inoculated with 10 ml of water, and incubated at body temperature for 10-24 hours. If the liquid in the tube turns yellow, and fluoresces blue when illuminated with a battery-operated, hand-held ultraviolet light, the presence of E. coli in the water sample is confirmed. If the tube remains clear, or is yellow but does not fluoresce blue under UV light, it indicates that there were no E. coli cells in the 10 ml sample, and there is a low risk of disease from the water.

Heat from your own body can be used as a incubator in the field.

The second test is a quantitative test using the E. coli count, Petrifilm (3M Microbiology Products, St. Paul, Minnesota), which is used extensively in the food industry. One milliliter of the water sample is added to the Petrifilm, which is incubated at body temperature for 10-24 hours. If E. coli is present in the water sample, it will develop into a blue colony surrounded by gas bubbles. By counting the number of blue colonies with gas, the number of E. coli in a milliter can be determined. One E. coli colony on a Petrifilm indicates heavily contaminated water and a high risk of disease, 10 or more E. coli on a Petrifilm indicates grossly contaminated water and a very high risk of disease.

Commercial water pasteurization devices

[[Video:Solar Water Pasteurization|thumb|400px|right|Video showing use of the AquaPak and the WAPI]]

SODIS

To see information on solar water disinfection (without the use of heat), see main article: SODIS

Topics needing research

Nitinol as a temperature indicator

Nitinol (Nickel-Titanium) is a memory metal which can be designed with a temperature transition threshold. It can be designed with two memory shapes: straight for below 65°C and circular for above 65C. Nitinol wire can be manufactured on a mass scale to provide an accurate indicator. The wire can be submerged into the water without a glass enclosure. When the wire becomes circular, the water temperature will have reached the 65°C threshold.

See main article: Topics needing research

See also

- Water pasteurization indicator (WAPI)

- Flow-through pasteurization device"p

- Safe Water Project

- A Summary of Water Pasteurization Techniques - Dale Andreatta

- Solar Water Disinfection in the northeast of Brazil: Kinetics of the Microbiological Process and the Study for the Development of the Pilot Plant - Paulo Mário M. Araújo

- Dr. Bob Metcalf

- Using beeswax to indicate pasteurization temperature

- Solar puddle

- Solar Kettle-Thermos Flask

- Soda bottle pasteurizer

- Solar Water Disinfection (SODIS)

- Another soda bottle pasteurizer

External links

- January 2009: Dr. Dale Andreattaspeaking on water pasteurization at the 2009 ETHOS conference - Dale describes the development of the WAPI, a simple device for determining whether water has been heated to a temperature that makes it safe to drink. He also discusses flow-through pasteurization devices and strategies to pasteurize water with the waste heat from a wood-burning cookstove.

- September 2007: Bob Metcalf interviewed on Sacramento NPR program

- September 2007: Safe Water from Sunshine - Patricia McArdle

- July 2006: Bob Metcalf's Granada conference presentation on solar water pasteurization. Audio: 16k, 8k and slides

- A slideshow showing Dr. Metcalf's solar water pasteurization projects in Africa

- An interview with Bob Metcalf discussing food safety and solar water pasteurization

- Pasteurization of Naturally Contaminated Water with Solar Energy - Applied and Environmental Microbiology, Feb. 1984, p. 223-228

- Recent Advances in Solar Water Pasteurization

- Solar Cooking Archive page on solar water pasteurization

- Colilert

- The Solar Puddle - Dale Andreatta

- Petrifilm is available from Arrow Scientific

- Construction plans for a simple solar water pasteurizer

- March 2007: Major development in drinking water testing technology - International Aid & Trade