Tom Sponheim (talk | contribs) mNo edit summary |

Tom Sponheim (talk | contribs) mNo edit summary |

||

| (6 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

{{GoogleTranslateLinks}} |

{{GoogleTranslateLinks}} |

||

| + | {{Updated|3|28|14}} |

||

| − | |||

[[File:Gallagher_Solar_Injera_Cooker.jpg|thumb|350px|[[Solar Injera Cooker]]]] |

[[File:Gallagher_Solar_Injera_Cooker.jpg|thumb|350px|[[Solar Injera Cooker]]]] |

||

[[File:Gallagher_diagram_cook_pan.jpg|thumb|500px|right|Solar Injera cook pan cross-section]] |

[[File:Gallagher_diagram_cook_pan.jpg|thumb|500px|right|Solar Injera cook pan cross-section]] |

||

| − | The '''Solar Injera Cooker''' has been designed by [[Alan Gallagher]], a retired physicist. He decided to take his interest in solar energy in a whole new direction: He decided to design, build, and test a unique large-area frying pan heated by the Sun’s energy. The new parabolic solar frying pan was specifically tailored to the cooking of [[injera]] bread in East Africa. Other types of solar cookers are not well-suited for frying. In villages, a typical “slice” of injera bread can be more than half a meter in diameter. The [[parabolic solar cooker]] can be used eight hours a day throughout the year. The bread is cooked for about two minutes in a covered pan preheated to ~ |

+ | The '''Solar Injera Cooker''' has been designed by [[Alan Gallagher]], a retired physicist. He decided to take his interest in solar energy in a whole new direction: He decided to design, build, and test a unique large-area frying [[pan]] heated by the Sun’s energy. The new parabolic solar frying pan was specifically tailored to the cooking of [[injera]] bread in East Africa as well as other types of [[flatbread]] prepared in other areas. Other types of solar cookers are not well-suited for frying. In villages, a typical “slice” of injera bread can be more than half a meter in diameter. The [[parabolic solar cooker]] can be used eight hours a day throughout the year. The bread is cooked for about two minutes in a covered pan preheated to ~{{Degree|80}}. |

The mirror consists of flat hexagonal panels of aluminized Mylar inside of a parabolic framework. The flat panels uniformly illuminate (evenly heat) the bottom of the frying pan, which sits above the mirror. The flat panels make this mirror safe to use for cooking because they don’t ever concentrate the sun in just one place, which can burn the cooks or start fires. The pan bottom is coated with a special black surface that only emits very low levels of radiation. The black surface keeps the fryer from losing as much as half the power it gets from the sun. The pan’s nonstick surface is made from anodized aluminum whose pores are filled with cooking oil. |

The mirror consists of flat hexagonal panels of aluminized Mylar inside of a parabolic framework. The flat panels uniformly illuminate (evenly heat) the bottom of the frying pan, which sits above the mirror. The flat panels make this mirror safe to use for cooking because they don’t ever concentrate the sun in just one place, which can burn the cooks or start fires. The pan bottom is coated with a special black surface that only emits very low levels of radiation. The black surface keeps the fryer from losing as much as half the power it gets from the sun. The pan’s nonstick surface is made from anodized aluminum whose pores are filled with cooking oil. |

||

| − | The retail cost of the materials (in the United States) to construct the solar fryer is about |

+ | The retail cost of the materials (in the United States) to construct the solar fryer is about USD 100, but the estimated cost for bulk manufacturing is only about USD 25. Most of the construction requires only hand tools, which is ideal for local production in East Africa. The design is scalable, making it relatively easy to construct smaller or larger fryers, if desired. |

| − | + | Included is a detailed description of the construction, an explanation of how the reflector is adjusted throughout the day to maximize cooking heat, as well as, information on the unique challenges faced when cooking injera bread with solar power. |

|

==See Also== |

==See Also== |

||

| Line 22: | Line 22: | ||

[[Category:Solar cooker designs]] |

[[Category:Solar cooker designs]] |

||

[[Category:Parabolic solar cooker designs]] |

[[Category:Parabolic solar cooker designs]] |

||

| − | [[Category:Foods]] |

||

Latest revision as of 19:32, 27 April 2020

|

Last edited: 28 March 2014

|

Solar Injera Cooker

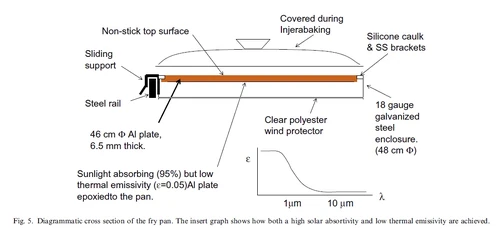

Solar Injera cook pan cross-section

The Solar Injera Cooker has been designed by Alan Gallagher, a retired physicist. He decided to take his interest in solar energy in a whole new direction: He decided to design, build, and test a unique large-area frying pan heated by the Sun’s energy. The new parabolic solar frying pan was specifically tailored to the cooking of injera bread in East Africa as well as other types of flatbread prepared in other areas. Other types of solar cookers are not well-suited for frying. In villages, a typical “slice” of injera bread can be more than half a meter in diameter. The parabolic solar cooker can be used eight hours a day throughout the year. The bread is cooked for about two minutes in a covered pan preheated to ~80 °C (176 °F).

The mirror consists of flat hexagonal panels of aluminized Mylar inside of a parabolic framework. The flat panels uniformly illuminate (evenly heat) the bottom of the frying pan, which sits above the mirror. The flat panels make this mirror safe to use for cooking because they don’t ever concentrate the sun in just one place, which can burn the cooks or start fires. The pan bottom is coated with a special black surface that only emits very low levels of radiation. The black surface keeps the fryer from losing as much as half the power it gets from the sun. The pan’s nonstick surface is made from anodized aluminum whose pores are filled with cooking oil.

The retail cost of the materials (in the United States) to construct the solar fryer is about USD 100, but the estimated cost for bulk manufacturing is only about USD 25. Most of the construction requires only hand tools, which is ideal for local production in East Africa. The design is scalable, making it relatively easy to construct smaller or larger fryers, if desired.

Included is a detailed description of the construction, an explanation of how the reflector is adjusted throughout the day to maximize cooking heat, as well as, information on the unique challenges faced when cooking injera bread with solar power.

See Also[]

External links[]

Contact[]

- See Alan Gallagher.Alan Gallagher