|

Last edited: 15 May 2016

|

This article was written for this Wiki by Bernhard Müller, Eschborn, Germany

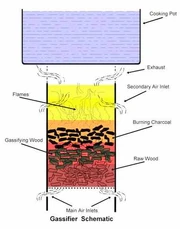

Diagram of the Hobo Gasifier Stove

Gasifiers are also called micro-gasifiers or woodgas stoves. They provide the cleanest combustion of dry biomass, such as wood, briquettes, etc. (Source: US EPA). In combination with fireless cookers, gasifiers are the answer to the question "what if the sun does not shine?" and therefore complement solar cookers in a brilliant manner.

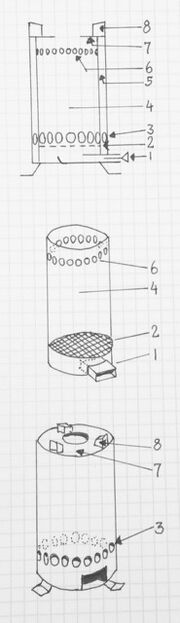

First, the gasification process will be explained in this paper: it is called pyrolysis and stems from the Greek words pyr (fire) and lysis (solution). The dry biomass releases wood gas under the influence of heat and absence of air. At the end of the process, charcoal remains for further applications. In contrast to carbonization in a kiln or carbonizer, the wood gas (smoke) is used for cooking purposes, emitting very low carbon monoxide (CO) and particulate matter (PM) exhaust gases. This distinguishes the great advantage of gasifiers. They can replace dirty combustion methods like 3-stone fires or charcoal stoves. Gasifier fumes are almost harmless (under ideal conditions and when the device is operated correctly!), allowing indoor cooking. Gasifiers save fuel. Example: to bring 5 liters of water to a boil, >1.3 kg of wood needs to be burned to ashes in a 3-stone fire. By utilization of a gasifier, just 0.45 kg of dry biomass do the same job - with 53% less fuel. As a bonus, the gasifier leaves 90 grams of charcoal, which is called "biochar" to indicate the production difference. A basic model of a gasifier, like the one described in this paper, has a thermal transfer efficiency of 50% to 55%. The sketches explain the gasifier. First the entire device is displayed, below you will see the reactor (inner cylinder) and then the outer shell construction.

How is a gasifier usually designed?

- This paper explains a TLUD (pronounced: tee-lud) gasifier with natural draft. The abbreviation means Top-Lit, Up-Draft.

- The primary air, which approaches and transits through the fuel from underneath, must be controlled (1) because it has to be reduced during the process of pyrolysis to nearly eliminate the toxic gases.

- The reactor (4) is a narrower cylinder inside the outer shell. It should be made of stainless steel to extend its durability. The grate (2) is fixed inside the reactor right above the primary air inlet (1).

- The secondary air is not controlled. It enters the empty space between both cylinders, gets hot and moves upwards due to its expansion (5).

- Subsequently, the hot secondary air enters the reactor through the holes (6), mixing with the pyrolytic gases and eventually shaping flame jets. The concentrator ring (7) ensures that the flames are forced to merge and hit the pot, situated on the pot rests (8), from underneath.

- The vertical distance from the secondary air holes of the reactor (6) to the concentrator ring (7) is about 2.5 cm (1 inch).

How do I cook with a gasifier?

Put the solid biomass fuel into the reactor up to approximately 2.5 cm (1 inch) underneath the secondary air inlet holes. Light the fuel from above, e.g. with a charcoal starter. Wait for about one minute until flame jets appear at the secondary air holes of the reactor. Suddenly, there is no smoke anymore. The stove can now be moved inside the house. The fuel does not burn, but the gases. The fuel is just glowing. Due to the heat radiation from the flame jets, this glow is kept alive and moves slowly downwards. This phenomenon is called migratory pyrolytic front (MPF). Once the MPF reaches the grate, the fuel is charred. The process comes to an end. Smoke appears again. The stove shall be moved now to open air again.

What to do now? Once the pyrolysis is finished, there will be no flame jets anymore. One has two choices: 1) Open the primary air inlet completely and continue cooking with the biochar. This option is less recommended for two reasons: a) that way you will produce a high amount of carbon monoxide (CO) like a charcoal stove, and b) this causes much stronger corrosion; 2) Pour the embers out of the gasifier and extinguish them by sprinkling some water on them. Use the dried biochar later for cooking or soil regeneration purposes.

Which fuel can be used?

Any dry biomass, like pellets or chopped wood is just fine. The fuel must be of uniform size with the maximum dimensions of 1.5 cm by 1.5 cm. The length must be less than 1/2 diameter of the reactor.

When is it necessary to apply a fan (forced draft)? In case the fuel particles are too small to allow a good circulation of the pyrolytic gases (e.g., rice husks or crude sawdust), a fan must be mounted to the primary air inlet. Natural draft gasifiers produce a bit more particulate matter, while forced draft gasifiers a bit more CO2.

Advantages

- Gasifiers are economical in fuel consumption

- Gasifiers can be operated indoors during the pyrolysis (under ideal conditions and when the device is operated correctly!)

- The process leaves biochar for various purposes. The char can even be sold

- Gasifiers are a strong, safer and cheaper option to LPG stoves

- Gasifiers complement solar cookers and heat-retention cookers

Disadvantages

- Gasifiers, especially those with fans, are too expensive for low-income households

- Gasifiers are batch-loaded. Re-fueling during the cooking process lead to dissatisfying results

- The fuel must be dried and processed to uniform sizes

- It is difficult to cook during windy conditions

- The correct handling requires several days of thorough instructions.

NGOs in East Africa who offer TLUD gasifier instruction

- Natural Resources and Waste Management Alliance (NAREWAMA), Nairobi, Kenya

- SURE Solar, Kisumu-Nyanza, Kenya

- African Christian Organization Network (ACON), Bungoma, Kenya

- Giving Hope Foundation, Kampala, Uganda

Conclusion

This paper has been compiled according to internationally available knowledge as per the end of the year 2015. Research for better performance is done continuously. It can be expected that better designs will be issued from time to time. Complete explanations can be found at the documents of my advisors and friends Christa Roth: https://energypedia.info/File:Micro_Gasification_2.0_Cooking_with_gas_from_dry_biomass.pdf and Paul Anderson (Dr. TLUD): http://www.drtlud.com . Thanks to the team of Awamu Biomass Energy Ltd., Kampala, Uganda under the leadership of Nolbert Muhumuza (www.awamu.ug) and Salim Shaban of African Christian Organization Network, Bungoma, Kenya (www.mwotostove.com) for presentations how to produce gasifiers under the harsh African conditions. Thanks to Richard Fetzner, Bruchsal, Germany for basic instructions.