|

Last edited: 17 February 2019

|

Celebrity chef José Andrés is an advocate of solar food drying.

Solar food drying is a form of solar food processing which uses airflow and solar energy to dehydrate food for consumption and storage. One of the simplest methods is to place thinly sliced food outdoors on a well-ventilated surface to dry in warm air. More advanced options, such as enclosed drying racks which utilize solar-powered fans to move air across the food, can be constructed or purchased.

Solar food drying background

Draping food over branches or spreading it on wide shallow baskets on the roof is an old, widespread tradition still in use around the world. Many other arrangements have been used to support a thin spread of food pieces. Some options that have been used are to thread the pieces on a cord or a stick and hang it over a fire or wood stove or from the rafters. Or one can bundle herbs or strawflowers and suspend them from bushes or a door knob or nails in rooms with good ventilation. Screen doors placed across chairs or sheets hung between clothes lines or possibly on a quilting frame have also been used. Vans, clean garages, or backseats of cars can be safe places to spread trays of drying food just as well as specially constructed cabinets. In the pioneer tradition food might be spread in the attic or in an upstairs room with screened windows wide open.

Modern variations are to build special enclosed drying racks or cabinets to expose the food to a flow of dry air heated by electricity, propane, or solar radiation. These are refinements not essential to the basic process but handy, particularly in the humid tropics or when the rainy season coincides with the harvest.

News

- January 2019: Solar Energy Drying in Haiti: Reducing Peanut Loss - In 2019, Sun Buckets in partnership with Acceso Peanut Company committed to research the causes and extent of postharvest peanut loss in Haiti and design, build, and field test a prototype crop dryer utilizing solar thermal storage, a product that can also be used for household cooking. Throughout Haiti, the domestic peanut market is characterized by low production volumes and high seasonal price volatility. As such, Haitian peanut farmers often store their peanut harvest for several months until they are able to receive more favorable prices in the market. Often, the crop is exposed to humid conditions without proper ventilation leading to contamination. Through this commitment, Sun Buckets will test the hypothesis that drying practices are the foundational cause of most peanut losses and create a prototype storage container that collects, stores, and recovers solar thermal energy to not only heat air and product, but also move air as needed for a dryer.

- June 2018: MAROC - De nouvelles coopératives équipées de séchoirs solaires - (English version)

- May 2018: Solar cooker/dryer combination - Muhammed Yasin Khan, living in Pakistan, offers his version of a solar box oven with an added solar dryer attachment. When not used for cooking, a vent at the top of oven can be opened to allow hot air to circulate through the upper chamber, which has a number of open shelves suited for drying fruits and vegetables.

- September 2017: Mujeres tacanas usan cocinas solares para secar semillas y convertirlas en artesanía - (English version) - Página Siete

Kua O Ka La school in Hawaii has converted an old school bus into a solar dehydrator. Photo credit: Kua O Ka La

- July 2017: Old school bus becomes a solar dryer - The resourceful staff and students at the remote Kua O Ka La Public Charter School in Pū‘ala‘a, Hawaii, USA, have converted an old school bus into a solar food dehydrator. Off grid, a primary goal at the school is to be able to run everything with solar power. More information...

A solar dryer fashioned from recycled windows and doors. Photo credit: Joshua Guinto

- January 2017: Solar dryer from recycled glass panels - Joshua Guinto has provided photo documentation of the construction of a solar dryer using recycled windows and doors. Read more about the project here: Solar Dryer in Wings, from old windows and doors - Joshua Guinto

- April 2016: Solar processing food waste - Avery Goho, student and inventor, and Gustavo Lascano, Animal and Veterinary Sciences faculty member at Clemson University, South Carolina, USA, are developing a solar box oven system to dry restaurant and grocery store produce waste and recycle it locally to farmers for animal feed. More information...

The Dehydratador Hybrid P.S_6 from Pleno Sol

- August 2015: New solar food dryer is capable of wireless temperature control - The new food dryer from Pleno Sol offers remote temperature control, but does require standard household electrical current to power fans and temperature sensors.

The new SunDryer50 available from IDCOOK.

- July 2015: New solar food dryer available from manufacturer in France - IDCOOK has announced they will begin taking orders for their new SunDryer50.

Diagram showing the role the solar dryer plays in helping produce dried fruits, vegetables, and briquettes for fuel-efficient cookstoves.

- December 2014: Joshua Guinto, a specialist with Appropriate Technologies, has provided an update on recovery developments in the Philippines in the wake of typhoon Haiyan. Their focus has been on providing solar dryers to dry fruits and vegetables, as well as to dry wood for bio-char and briquette production for use in fuel-efficient cookstoves. Read more at: The Approtech Training for Salcedo Eastern Samar - Joshua Guinto, November 2014.

- November 2014: Brian White reports: "I have a thing in the works for solar drying with calcium chloride as a desiccant. Dry calcium chloride absorbs water and becomes liquid in the water that it absorbs. It actually has a pretty complex series of crystal hydrates that all absorb water, and calcium chloride is cheap and food safe. So, I am planning to use a solar cooker to drive off the water and "recharge" the calcium chloride. My main problem with solar cooking is that I am rarely home during the day. Using a solar cooker to build up a big store of very dry calcium chloride to dry fruit in the fall might be a good idea. Then you put the calcium chloride in a closed solar dehydrator with the fruit and a little fan and the water gets transferred to the calcium chloride, which drips out of the thing as it becomes liquid. I am also looking into making calcium chloride from limestone and brine. It can be made with a solar panel electrolyzing the salt. You get hydrogen and chlorine that you can recombine above in moist limestone chips. This converts some of the calcium carbonate in the limestone to calcium chloride. This might seem like a waste of a solar panel, but the industrial process to produce calcium chloride is similar."

- October 2014: Bernhard Müller is working on the development of a counter-current solar food dryer which saves 50% on space and materials compared to common solar tunnel dryers. Involved in the development are Faustine Odaba of NAREWAMA, John Amayo of SURE, Prof. Wilson Ogola of the Technical University of Kenya as well as some experts from Uganda.

Sizzling Solar Systems dehydrator

Heating the thermal mass (water bottles) to help provide stable nighttime temperatures and avoid mold formation on the fruit.

- November 2012: Solar Food Dehydrator - Stan Cajdler of Brisbane, Australia, has developed a solar food dehydrator, which significantly reduces the formation of mold spores caused by the nightly cooling of food. Typically, the drying process can last for several days for successful solar food drying. In this design several water containers (for thermal mass) are positioned in the lower chamber of the dehydrator. As the collector plate heats up, it heats up the surrounding air, which rises through the drying chamber. During the day, radiant heat from the collection plates also heats the water containers, which slowly release heat overnight. This overnight thermal air movement through the upper chamber dramatically reduces the formation of mold spores. For more information on Stan’s solar cooker designs check out: Sizzling Solar Systems

UC Davis team demonstrating the solar dryer.

- October 2012: Foresight Technology has developed a lightweight, large-capacity portable solar food dehydrator. It is highly effective. Its unique four-sided absorber design allows for an extended daily drying period. It is available for shipping.

- February 2011: A group from the UC Davis Program for International Energy Technologies installed a solar box dryer for drying fruit in Nicaragua. They worked with the local organizations Grupo Fenix and the Solar Women of Totogalpa. They also connected with students and faculty at the Alternative Energy Program at Nicaragua's National Engineering University and the directors of the new dried fruit export company SolSimple. They plan to send a follow-up trip during the summer of 2011. More Information...

- May 2006: John Maina of Kenya wins the Energy Globe Award for 2006 – Employing solar energy for drying food & gaining income security. In Kenya, 30-40% of vegetables and fruits are lost due to poor post-harvest handling. The lack of firewood, which is necessary for drying and treatment of durable goods, is one of the major reasons for the loss. Since 2002 SCODE (Sustainable Community Development Services) has employed a solar dryer in Kenya for the drying of harvested produce. The advantages are obvious: solar energy is free and available virtually everywhere. The fresh produce can be made durable in a cheap way and market value will be increased. As a result of the fast drying process, the farmers can raise harvesting production and are therefore able to generate additional income – this means up to 50% more productivity. The time needed for collecting firewood before can now be used for various other activities and deforestation is reduced as well. Currently 30 solar dryers have been installed and 920 farmers have been trained in their use. Thirty craftsmen have also been trained in the construction and installation of these solar dryers. The project contributes to an overall improvement of living conditions, family nutrition, environment protection, and income generation. At the moment the project is implemented in the Rift Valley in Kenya and has the potential to be duplicated in other areas.[1]

Types of solar dryers

Updraft solar dryers

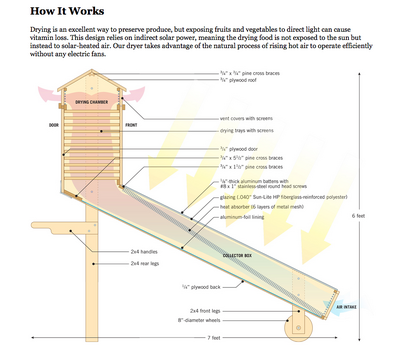

Updraft solar dryer design schematic. - Mother Earth News

Updraft solar dryer designs are most frequently seen in cabinet form. With this design, the hot air flows upward through a solar heat collection trough and enters the bottom of a cabinet underneath the food. The dry air rises through the trays and around the food, exiting through a vent at the top or near the top of the shadowed side (see bibliography below – Valdez). The theoretical basis for this design is that hot air rises and therefore when the air is heated, it flows naturally upward through the trays of food. See plans for the Dennis Scanlin (Appalachian State University) solar dryer from Mother Earth News.

Direct heat dryers

Example of a direct heat solar food dryer. - Tom & Erin - "This Bahamian Life"

Directly heated cabinet dryers allow the sun to heat and dry the food inside an enclosed well-ventilated one-piece cabinet. Direct heating tends to be very efficient and produces fast drying. Proper air flow is essential to achieve maximum performance.

Solar food dryers can be hybridized so they continue to dry during cloudy weather. Removing a tray or two from the bottom, a very small flame from a 475 ml (16.1 oz.) or picnic-sized propane burner can be placed on the bottom. (Alternately a small electric heating unit may be used.) Heat rises and triggers the same effect as the solar heat. It is important to avoid overheating the food, maintaining temperatures below 50 °C (122 °F).

Solar tunnel dryers

Solar tunnel dryer. - Klaus Triebe

Farmers and agricultural processing companies have taken the solar drying approach to the next level. In order to be able to dry significant quantities of product at one time, structures are used incorporating long narrow drying chambers, usually vented by electric fans powered by photovoltaic panels (PV).

Typically, a long drying table is put in place and then an enclosure framework is erected and covered by clear or translucent plastic sheeting. Fans are installed at one of the open ends, which drives the moist air from the harvested food out the other end. Using a lightweight system and photovoltaic power allows the dryer to go into the fields and process foods where they are harvested. This saves time and allows transporting less weight after the food is dried.

Solar Bubble Dryer developed by GrainPro, Inc. in partnership with the International Rice Research Institute (IRRI) and Germany’s Hohenheim University. Read more... - Solar Thermal Magazine

Some systems, called solar bubble dryers, use fans powerful enough to actually inflate the enclosure, avoiding the necessity of erecting a skeletal framework to hold the plastic covering in place. In developing countries solar drying may be the cheapest and most feasible method for drying foods, but in developed countries, with more processing options, relying on the availability of enough sunshine can put crops at risk.

Tray Design

Screen materials

Trays need not be bulky, and in fact lightweight ones with open screening block less airflow and so are preferable. Screening may be woven out of local materials or may be commercial screen of non-toxic materials such as nylon and some plastics. Fiberglass window screening is not recommended as it is coated with vinyl that may contain flame retardants and other chemicals. Open weave organic fibers and nylon material works fairly well, but can be difficult to clean. The usual commercial bridal veil is too fragile to last as screening on the trays but may be spread over top to control insects. Avoid screen materials that may contain toxic chemicals or additives. Galvanized metal screens or aluminum or copper screens are not recommended as potentially toxic salts can migrate into the food. Top quality food-drying screens are made from food-safe plastic screening, such as polypropylene, which is available from Living Foods Dehydrators and SunWorks Technologies (also see bibliography below).

One or two heavier screens made from 2.5 cm (1 in) x 5 cm (2 in) pine and covered with galvanized hardware cloth are useful for drying non-food items – clothing, wool, kindling, and so forth. For support of extra-heavy loads, rigid galvanized trays may be used under a food-safe screen. Galvanized screens may also be used to make fruit leathers. The sauce is protected from the galvanized metal by a sheet of Tedlar or by regular kitchen plastic taped to the frame.

Tray frames

Trays, if used, are sized to comfortable dimensions, for instance 70 x 70 cm (24 x 24 in) or 51 x 76 cm (20 x 30 in). Then a supporting rack is made to that size. Air flow is essential, so it is important that trays be sufficiently far apart to ventilate properly – 15 to 20 cm (6 to 8 in) if using natural ventilation, less for forced ventilation. Tray frames should be light but strong – small wood strips, 3 cm x 6 mm (1.25 in x 0.25 in) or 2 cm x 1.25 cm (0.75 in x 0.5 in) in size, are sufficient for most purposes. The wood strips for the tray frames are cut to the full length and the full width of the tray. They are overlaid at the corners, notched if they are very thick, glued, and screwed. Or they may be nailed with small nails which are bent over on the underside and pounded flat. The screen is stapled on and may be secured with silicon sealant or thin lightweight wood, or both.

Working with your trays

If indoors, it is easy to use screened trays placed around on chairs or saw horses. No further equipment may be needed. If outdoors, the food must be protected against insects and animals and moved or covered in case of rain or blowing dust. Exposed trays also must be carried in at night and out again in the morning to prevent rehydration from the dew, even in the desert.

A single layer of trays outdoors may be covered with sheets of cotton, glass, or plastic through which the sun falls on the food. Sunlight heats the food, driving out moisture. The moisture-laden air falls down from the bottom of the screened trays. In this generic design, the food is usually exposed to direct sunlight, which destroys some of the more fragile vitamins and enzymes and causes the food to lose color. The better- quality food is produced by flat-screen designs having a dark sheet of cloth or metal that shades the food. This metal shield slows the drying, but these designs are still very productive. Their disadvantages are that they spread out over a larger area of ground than the cabinets and they tend to blow over in gusty wind.

One simple open-air dryer design that can be used indoors or outdoors is called the Kerr-Cole Z-dryer. This is a rack of trays 15 to 20 cm (6 to 8 in) apart stacked in a frame. The frame of open racks is braced with a diagonal piece of wood forming a Z (see the bibliography: Z-dryer). The frame can be sized to fit an available space such as the back of a car or some place in a well-ventilated room, etc. Also, Z-dryers can stand in the yard, optionally covered with a light cloth, or one can be fitted to go into a solar heated, ventilated cabinet such as a downdraft solar food dryer. Without increasing drying time very much, such an open rack may be covered with a lightweight cloth to protect from insects. Ants and other crawling insects may be blocked from the trays of food by placing the feet of a rack in containers of water. Such moats can be used with any of the stacked designs. If ants and some other insects invade the drying racks, it is difficult to remove them. However, they will go home at night. Protective measures instituted early the next morning can block their return.

Solar dried foods

Food preparation for drying

A solar box cooker being used as a solar food dryer. Note that the lid is placed slightly ajar to allow the moisture being released from the food to escape.

Food drying is not difficult, although some books give considerable details on handling each food differently. Special guidelines are needed for handling jerky and fish (see bibliography and your own recipes). General guidelines for fruits and vegetables follow:

- Use good-quality food cut in thin pieces, not more than about 6 mm (1/4 in) thick.

- Spread thinly on trays initially so there is a third to a half of the screen area clear for the passage of air (food can be more compact after the first moisture is gone).

- Label all food on the trays and carry the label along through processing to storage.

Thick vegetables need to be blanched or lightly pre-cooked. Leafy vegetables may be wilted slightly with steam, or dried directly from the garden. Cook potatoes and green beans completely. Pretreat fruit by dipping in quite sour lemon water or ascorbic acid (Vitamin C), 2,000 mg (.07 oz) / 1.1 litre (1 qt). After a short soak, drain the fruit and spread on trays (this retards browning, and later the sour soak water flavored by the fruit can be used as a concentrate for making cool drinks). Sugar, honey, or salt are optional. Sulfuring is no longer used in most homes because of the possibility of breathing the hazardous fumes and experiencing allergic reactions to sulfur compounds. (It has been found to be unnecessary anyway.)

To test if food is sufficiently dried, remove a piece and let it cool. Vegetables should be brittle. Fruits, because of their sugar content, may never get beyond a firm bend or leather quality and it is okay if they become a little brittle.They just need a little more soaking or chewing time for full flavor to develop.

All dried foods may be pasteurized after drying except for greens and herbs. Spread dried food no more than 2.5 cm (1 in) thick on a metal tray and cover it with another dark metal tray. (A solar oven is excellent for this.) Place it in an oven at a temperature between 93 °C (199 °F) and 105 °C (221 °F) for 10 minutes. Stir and leave another 10 minutes – do not overtreat. Cool and package immediately, storing in a dry location as cool as possible.

Storing solar dried food

For people on the move or with limited storage space, plastic freezer bags are safe, durable, and easily transported. Food should be put in small clean bags, labeled, and dated. The smaller bags can be grouped into larger freezer bags, giving larvae two layers to penetrate if they attempt to invade. For those who avoid plastic, glass jars or metal containers with tight lids do well. Pack to eliminate air.

Indians in the American Southwest sometimes stored dried food in large earthen jars packed very tightly and covered with leather tied on tightly. These jars were kept on the roof and so were subject to low temperatures at night. Others stored dried food in hay-lined pits lined with flat rocks to deter rodents. These pits were so deep a person had to be assisted to get out. These were covered with leather or boards as a rain protection.

All stored food should be checked periodically for weevils, which are small, relatively clean insects. Infestations come from eggs hatched in storage areas. They grow to about 13 mm (1/2 in) long and then go into a small webbed cocoon. The mature form is a thin, gray-brown moth about 13 mm (1/2 in) long. Infestation can be controlled by eliminating the adult moths before they lay their eggs. Once hatched, the larvae feed only on clean food. The form most prevalent in the USA is found as white, soft-bodied active "worms" with dark heads. Since they feed only in the stored food, they do not usually carry disease or toxic contamination. Even if the larvae themselves are not visible, weevil infestation is easily recognized. Small brown granules in the bottom of the packages or 13 mm (1/2 in) bits of white webs indicate infestation. The same pasteurization method can be used to kill adult and immature weevils. Treat and then sift out the residue. Pasteurized dried goods rarely show infestation if stored in airtight containers, but if stored in bread bags, they almost always will.

Cooked weevil-infested food is usually safe to serve and eat if food is scarce. Some cooks on seeing larva facetiously say "Just a little clean protein ... God's gift to vegetarians." But prevention is the best policy. Clean, quick handling and good packaging is the key, along with storing at the lowest available room temperature – below 21 °C (70 °F) there is little or no weevil activity.

Cooking with dried foods

Drying and storing food is a simple process. Using dried food can be equally simple. Fruits or vegetables may be eaten out of hand, or fruit may be rinsed with water, drained briefly, and placed in a closed jar in the refrigerator to soften. Any of the dried produce may be covered with boiling water to slightly above the food level. Food should then be tossed to ensure all parts of the dried bits are in contact with water. Most foods are allowed to stand for 15 minutes (equal parts packed food and water) before being added to standard recipes. Heavier pieces may require more time to rehydrate to the center. Easier yet, they may be just thrown in dry by the handful into soups or casseroles. Crisp dried foods may be pulverized in a blender and added by the spoonful to recipes for breads, soups, casseroles, sauces, etc.

For instance, greens can be used as a regular dish by pouring boiled water over them and then continuing steaming for a few additional minutes depending on the type of green. Dried squash and small pieces of potatoes can be covered with boiling water plus about 13 mm (1/2 in) additional depth. They are then allowed to stand for 20 to 30 minutes to become moistened to the center before starting to cook. Larger pieces of potatoes require soaking for several hours.

Dried food is ranked by the US Department of Agriculture as more nutritious than canned food and slightly less nutritious than frozen food. The tastes of each are related to the food, but there is uniqueness in flavor and texture. This is similar to the differences between fresh, frozen, and canned foods ... another variation in taste.

Handbooks

- November 2016: Food drying attachment for solar panel cookers

- February 2016: Handbook on Solar Drying - Planters Energy Network

- Best-Ever Solar Food Dehydrator Plans - Mother Earth News

- Construction of Solar Cookers and Driers - Christelle Souriau & David Amelin (This is an excellent overview of solar cooking basics and simple solar cooker and dryer construction methods.)

Audio and video

- July 2017: Hawaiian school uses old school buses as solar food dryers.

- October 2013:

Articles in the media

- March 2018: Now, healthy and storable ‘solar dried food’ - The New Indian Express

- March 2018: AIWC promotes solar-dried veggies and fruits - The Hans India

- May 2015: Wasting Less of Africa’s Harvest in Order to Prosper - The New York Times

Documents

- January 2018: Simulation of a Solar Assisted Counterflow Tunnel Dehydrator (Paper) - A. Carrillo-Andrés

- January 2018: Introduction of Solar Drying by NGO Narmada in Nimar Region of Madhya Pradesh State of India Under the Guidance of Barc, Goi (Paper) - Raghav Deosthale, et al

- January 2018: Performance Testing of a Solar Thermal Fruit Dryer (Slides, Abstract) - Ricardo Bernardo & Pia Otte

- January 2018: Development of Solar Dryers, Cuban Experience for Food Preservation (Slides, Abstract) - Boris A. Zaldívar Núñez, et al

- January 2018: DryEcoMate – An Horticultural Dehydrator, Using Solar Thermal and Photovoltaic Energy, Low Cost Production, Modular and Portable (Slides, Paper) - J. Garcia, et al

- November 2017: Natural convection flow in a solar dryer geometry - José Núñez, Alberto Beltrán, Carlos A. García, and Bernardo López-Sosa

- February 2017: How to Stop Wasting Food … and Feed the World - Next Billion

- January 2017: Improved Fish Drying Using the UCD Chimney Dryer - Mohd Rezaul Islam, Amrita Mukherjee, Angelos Deltsidis, Michael Reid, Jim Thompson, Elizabeth Mitcham

- January 2017: Solar Drying of Chiapas's Fresh Cheese - Juana María Hernández Jarquín, Joel Pantoja Enríquez

- January 2017: Solar Drying of Horticultural Crops in Bangladesh - Amrita Mukherjee, Rezaul Islam, Michael Reid, James Thompson, Angelos Deltsidis, Elizabeth Mitcham

- January 2016: Extension of Shelf Life of Fruits and Vegetables by Solar Thermal Drying with High Solar Fraction in Temperate Climates (also paper) - Sonnenobst

- January 2016: Solar Cookers in the Antarctic, Solar Restaurants in Desert Areas, Use as Adaptable Solar Dryers - Pedro Serrano – Technical University Federico Santa Maria, Chile

- March 2011: Analysis of the Drying Kinetics of S. Bartolomeu Pears for Different Drying Systems - Electronic Journal of Environmental, Agricultural and Food Chemistry

- January 2009: Studies on Fortification of Solar Dried Fruit bars - G. Sarojini, V. Veena, M. Ramakrishna Rao

- January 2009: Solar Dryers For High Value Agro Products at SPRERI - T. V. Chavda & Naveen Kumar

- January 2009: Practical Application of Solar Tunnel Dryers - Klaus Triebe

- January 2009: Perspectives of solar food processing in India - C. Palaniappan

- January 2009: Drying Studies of Single Layer Thompson Seedless Grapes - R.L. Sawhney, D.R. Pangavhane, and P.N. Sarsavadia

- January 2009: Micro-enterprises in Solar Food Processing Technology - Case Study - M. Ramakrishna Rao, D.J. Rao, S.L. Kumar

- January 2009: Solar drying of fruits, vegetables, spices, medicinal plants and fish: Developments and Potentials - B. K. Bala & Serm Janjai

- January 2009: Solar drying of mushroom using solar tunnel dryer - B. K. Bala, M. A. Morshed, and M. F. Rahman

- January 2009: Thematic studies for processing and preservation of food supplement, chilies and ginger by drying through solar energy - Ranjita Bezbaruah Sharma

- January 2009: Processing of Vegetables in A Solar Dryer in Arid Areas - Navratna Nahar

- July 2006: Penetration Curves of Solar Heat into Date Fruits as a Mean to Control Insects - Alhussein Assiri

- July 2006: The Granada conference paper covering the construction and use of a solar coffee bean dryer in Chiapas, Mexico - Maria Cristina Martínez Sosa and Cesar Estrada Aguilar

- November 2000: Solar Dryer Systems and the Internet: important resources to improve food preparation - David Whitfield

- November 1984: Understanding Solar Food Dryers - Roger G. Gregoire, P.E.

See also

- Solar food processing

- Using a box cooker as a food dryer

- Simply Solar

- Example of Village Development in Afghanistan Based on Renewable Energy

- Information on solar dryers - Solar Energy Society of South Africa

- S. Padmaja has a company that sells solar dried fruits and vegetables in India.

- Dada Zanzibar produces jams and dried foods using solar cookers and dryers in Tanzania.

- Solar Tent

- CONSOLFOOD

- Delicias de Oaxaca

- Desidratador Hibrido P.S 12

- Khan's Solar Food Dryer

- Kiin

- KotoSec Solar Dryer

- Multipurpose Solar Dryer

- PRISMA hybrid solar dryer

- ParaSec Solar Dryer

- Pia Otte

- Practical Action

- Radha Energy Cell

- Rudra Solar Energy

- SimplaSec Plus Solar Dryer

- Simply Solar

- SolarFlex Food Dryer

- Solar Foods

- Solar cabinet dryer

- Solar food dryers

- TunnelaSec Solar Dryer

- Using a box cooker as a food dryer

External links

- Solar dehydration on Pintrist

- State Of The Art Solar Bubble Dryer™ Promises To Help Farmers Dry Their Commodities - Solar Thermal Magazine

- Fabrication de cuiseurs et séchoirs solaires

- Detailed Project Report on Solar Fruits and Vegetables Dehydration - Planters Energy Network

- Detailed Project Report on Solar Air Heating for Paddy Drying - Planters Energy Network

- Dissemination of Solar Drying Technology for Industrial Sector Including Agro-Industries in the Country - Planters Energy Network

- Development and Market Analysis for Integration of a PCM Storage in Solar Drying Systems - Planters Energy Network

- Solar Food Dehydrator - Sunkeep: lightweight, effective, large capacity solar food dehydrator

- Country Lore: Super-easy, Low-cost Solar Dehydrator

- Chris's ENGR305 Solar Food Dehydrator (made from cardboard) - Appropedia

- The Solar Food Dryer: How to Make and Use Your Own High-Performance, Sun-Powered Food Dehydrator, by Eben Fodor (2006)

- Solar Drying - presented by David Whitfield at the International Conference on Solar Cooking in Kimberly, South Africa, in 2000 (PDF version here)

- El Paso Solar Energy Association materials on solar drying

- Solar food dryers at Build It Solar

- Guia de Uso de secaderos solares - Martin Almada

- Full text of book: Solar and Energy Conserving Food Technologies: A Training Manual - (US Peace Corps, 1984, 175 p.)

- A large collection of documents on many aspects of solar drying - Practical Action

- August 2012: Argentino desenvolve fogão solar e invenções ambientais, no ES - G1 ES

- Storing the Harvest: Drying Fruits and Vegetables - Planet Natural

Solar food drying bibliography

- Erickson, Duane, produces a small, hanging, screened food dryer. Duane Erickson Enterprises, 1170 Elgin Avenue, Salt Lake City, Utah. 84106.

- Fodor, Eben, The Solar Food Dryer: How to Make and Use Your Own High-Performance, Sun-Powered Food Dehydrator, 2006 by New Society Publishers.

- Jagadeesh, A. Director, Shri AMM Murugappa Chettiar Research Centre, Tharamani, Madra - 600 113 INDIA. Designs of simple basket dryers.

- Kerr, Barbara. The Sustainable Living Center. 3310 Paper Mill Road, Taylor, Arizona 85939 USA. Schematic of downdraft design.

- LIVING FOODS DEHYDRATORS, 3023 352nd SE, Fall City, WA 98024. A source of food-safe plastic screening. They also supply an electric heating rack that might be used for hybridizing a solar drying cabinet.

- MacManiman, Gene, DRY IT -- YOU'LL LIKE IT. MacManiman, Inc., P. O. Box 546, Fall City, WA. 98024. 1973. (Non-solar as of 1992, but a good source of drying literature, materials and recipes. Their very fine design of drying cabinet depends on electricity but the trays can be placed in racks for solar drying if desired, returning them to the electric cabinet only when solar heat is not sufficient.)

- Susan McClure and the staff of the Rodale Food Center. PRESERVING SUMMER'S BOUNTY, a Quick and Easy Guide to Freezing, Canning, Preserving and Drying What You Grow. Rodale Press, Book Readers' Service, 33 East Minor Street, Emmaus, PA 18098. 1998 ISBN 0-87596-979-8

- Rodale Plans, SOLAR FOOD DRYER edited by Ray Wolf. Rodale Press, 33 East Minor Street,

- Emmaus, PA. 18049. ISBN 0-87857-333-X paperback. 1981. Out-of-print. If you can get an old copy, this is a good source of how to prepare and use dried foods. Also contains plans for a downdraft solar food dryer and information on scientifically knowing when food is dry enough.

- Valdez, Arnold and Maria, "A Cookbook for Building a Solar Food Dryer." A good updraft design and instruction of use of dried foods. Sangre de Cristo Printing. 924 Main Street, Alamosa, Colorado. 81101.

- Z-DRYER, Kerr-Cole Solar Box Cookers, P.O.Box 27417, Tempe, AZ, 85281. $1 plus large stamped envelope.

[The original text for this bibliography was provided by Barbara Kerr on November 2, 1998.]

All solar food dryers

All items (26)