Tom Sponheim (talk | contribs) m (→External links) |

No edit summary Tag: Source edit |

||

| (51 intermediate revisions by 7 users not shown) | |||

| Line 1: | Line 1: | ||

| + | {{GoogleTranslateLinks}} |

||

| + | {{Updated|5|18|21}} |

||

[[File:Biomass_briquettes.jpg|right|350px]] |

[[File:Biomass_briquettes.jpg|right|350px]] |

||

[[File:Briquette_press_2010.jpg|thumb|350px|Briquette press being demonstrated at [[Cyprus]] conference in 2010]] |

[[File:Briquette_press_2010.jpg|thumb|350px|Briquette press being demonstrated at [[Cyprus]] conference in 2010]] |

||

| + | [[File:Briquettes_burning_-_FoST_2019.jpg|thumb|350px|Briquettes burning. Photo credit: [[FoST]]]] |

||

| − | Collect any type of waste from you home or office including paper, cardboard boxes, saw dust, scrap wood, rice husk, fruit wastes, grass, leaves, kitchen wastes, agriculture and forest residues or industrial wastes. Shred ’em, cut ’em, soak ’em and hammer ’em and what you get is a pulp. A stinking good chunk of pulp. Now press the pulp, dry it for two to three days and what you have is your briquette, all ready to burn in a range of stoves ranging from mud stove with one burner to rocket stove and room chimneys. It is energy efficient, cost-effective, manages waste and moreover an inexpensive alternate source of energy that can fuel simple households to business houses. |

||

| + | Begin by collecting waste from around your home or surrounding area, including paper, cardboard boxes, sawdust, scrap wood, rice husk, fruit wastes, grass, leaves, kitchen wastes, charcoal dust, or agriculture and forest residues. Shred these and soak them. Next, squeeze the pulp in an improvised press to remove the water. |

||

| + | Finish drying the resultant [[briquettes]] for two to three days, and they will be ready to burn either in a three-stone fire or an [[:Category:Improved combustion stoves|improved combustion stove]]. The process is energy efficient, manages waste, and provides an inexpensive alternative energy source. Briquette production can also become an [[Business development|income source]] for those wishing to make the briquettes for resale. |

||

| − | A kilo of briquettes costs Rs. 16 (20 cents US) and a kg and half will take care of a day’s cooking for a family size of four,” Shrestha Arpan says, who just got back from training disadvantaged communities in Bajura, Humla & Jumla (Nepal) about this indigenous technology. “If we could take this technology to a larger scale, imagine what 600 tonnes of daily valley waste could be transformed into – 70 per cent of the waste could be utilized to make briquettes while the rest 30 could be used to manufacture compost,” she adds... |

||

| + | =={{HeadingNews}}== |

||

| − | Excerpt from [http://beacononline.wordpress.com/2009/09/04/nepal-toads-eye-view-way-forward-for-nepal;''The Himalayan Beacon'' website], Sept. 4, 2009. |

||

| + | *{{NewDec22}}'''December 2022: Making briquettes''' - Congolese [[AfriShiners]] member '''Guillain Maliyamungu Nabahya''' provided a link to a video on local TV broadcast about [[briquette]] making. Enjoy the show by clicking on the following link: [https://drive.google.com/file/d/1sdBL132Fj8eY2ofF10jiervCjwvv1C_A/view Briquette manufacturing]. AfriShiners member '''Millicent Anyango''' from Rongo, Migori County, [[Kenya]], is proceeding the same way with her briquette production. |

||

| − | {{clr}} |

||

| + | |||

| − | ==Audio and video== |

||

| + | *{{NewNov15}}'''August 2015:''' The [[Mount Kenya Energy Project]]'s German organisation [[Lernen-Helfen-Leben e.V.]] has focused on the construction of gasifier/pyrolysis stoves during the past three years. These stoves perform very well when pellets or [[Biomass briquette]]s made from plant waste are used. MKICDO board members came to the conclusion that making briquettes for sale could be a viable income-generating project for the Kiini workshop. It would also be in line with plans to build gasifier stoves at the new institute and train promotors to market them. Mugo found a young entrepreneur who already had some experiences in setting up such projects. We met and came up with a basic outline for a medium-scale business. The briquettes will be made of sawdust and coffee husks. Sawdust is readily available from carpentry workshops. The husks are a waste product at coffee dry mills and are sold very cheaply. Arrangements were made at a nearby coffee cooperative to be given priority for sales. |

||

| ⚫ | |||

| + | |||

| − | {{clr}} |

||

| + | [[File:Joshua_Guinto_solar_dryer,_bio-char_diagram,_12-11-14.png|thumb|300px|Diagram showing the role the [[solar dryer]] plays in helping produce dried fruits, vegetables, and [[Biomass briquette|briquettes]] for [[fuel-efficient cookstove]]s.]] |

||

| ⚫ | |||

| + | *'''December 2014:''' [[Joshua Guinto]], a specialist with Appropriate Technologies has provided an update on recovery developments in the [[Philippines]] in the wake of typhoon Haiyan. Their focus has been providing [[solar dryer]]s to dry fruits and vegetables, as wells to dry wood for bio-char and [[Biomass briquette|briquette]] production for use in [[fuel-efficient cookstove]]s. Read more at: [[Media:Guinto_Appprotech_Episode_of_Reconstruction_EAST_SAMAR_Nov_2014.pdf|The Approtech Training for Salcedo Eastern Samar]] - ''[[Joshua Guinto]], November 2014'' |

||

| + | |||

| + | ==Constructions plans== |

||

| + | *{{NewFeb16}}[[Media:Easy_BioPress_Micro_Compound_Lever_Press_02-16.pdf|Easy BioPress Micro Compound Lever Press]] |

||

| + | *[http://leehite.org/ewb_project.htm More information] |

||

| + | ==Variations== |

||

| + | ===Honeycomb biomass briquettes=== |

||

| + | [[File:Honeycomb_biomass_briquette.jpg|thumb|150px|Beehive briquettes and the briquettes mold (ICIMOD, 2009)]] |

||

| + | Briquettes make use of compacted agricultural wastes, including fallen dry leaves, for fuel. Beehive briquettes (a honeycomb beehive-shaped biomass briquette) are made using a hand mould. The air channels help the briquette burn more easily. |

||

| + | |||

| + | ==Resources== |

||

| ⚫ | |||

*'''January 2013:''' [[Media:Solar Cooking with Integrated Systems-FOST-2011.pdf|Solar Cooking with Integrated Systems]] - ''[[FOST]]'' |

*'''January 2013:''' [[Media:Solar Cooking with Integrated Systems-FOST-2011.pdf|Solar Cooking with Integrated Systems]] - ''[[FOST]]'' |

||

| − | == |

+ | ===Audio and video=== |

| + | *{{NewMay18}}'''May 2018:''' |

||

| − | *[http://www.engineeringforchange.info/2010/04/fuel-briquettes-put-energy-in-the-peoples-hands/ Fuel Briquettes Put Energy in the Peoples’ Hands] - ''Engineering for Change'' |

||

| + | ::[[File:FoST Lapu EN-0|thumb|none|400px|FoST demonstrates production of [[Biomass briquette|briquettes]] in Lapu Village in [[Nepal]].]] |

||

| + | *{{NewJun16}}'''April 2016:''' [http://info.arte.tv/de/mauretanien-die-plage-nutzen Video of a project in Mauritania showing how an invasive plant can be used to make charcoal briquettes] (French) |

||

| ⚫ | |||

| + | |||

| + | *'''October 2013:''' |

||

| + | ::[[File:Fuego del Sol Biomass Fuel Briquette Production '13-0|none|400 px]] |

||

| + | |||

| + | *'''June 2010:''' |

||

| ⚫ | |||

| + | |||

| + | =={{NewJun16}}NGOs using biomass briquettes== |

||

| + | {{DPL|NGOs employing biomass briquettes|NGOs employing biomass briquettes|1}} |

||

| + | |||

| + | ==External links== |

||

| + | *[https://web.archive.org/web/20120318192600/http://home.fuse.net/engineering/ewb_project.htm Open Source DIY Biomass Briquette Technology Design and Formulations] |

||

| + | *{{NewJun16}}[https://www.engineeringforchange.org/make-a-biomass-processor/ Make a biomass processor] - ''Engineering for Change'' |

||

| ⚫ | |||

| + | *[http://assets.helvetas.org/downloads/sys5_alternative_energy.pdf HELVETAS Swiss Intercooperation document containing information about their biomass briquette work] |

||

| + | {{InterwikiLink|Briquettes de biomasse}} |

||

| − | ==See also== |

||

| ⚫ | |||

| − | *[[Foundation for Sustainable Technologies]] (FoST) |

||

| − | *[[Rocket Stove]] |

||

| − | *[[Partnership for Clean Indoor Air]] |

||

| ⚫ | |||

Latest revision as of 20:27, 16 December 2022

|

Last edited: 18 May 2021

|

Briquette press being demonstrated at Cyprus conference in 2010

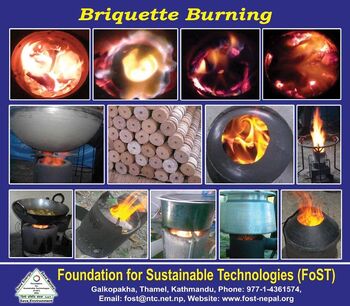

Briquettes burning. Photo credit: FoST

Begin by collecting waste from around your home or surrounding area, including paper, cardboard boxes, sawdust, scrap wood, rice husk, fruit wastes, grass, leaves, kitchen wastes, charcoal dust, or agriculture and forest residues. Shred these and soak them. Next, squeeze the pulp in an improvised press to remove the water.

Finish drying the resultant briquettes for two to three days, and they will be ready to burn either in a three-stone fire or an improved combustion stove. The process is energy efficient, manages waste, and provides an inexpensive alternative energy source. Briquette production can also become an income source for those wishing to make the briquettes for resale.

News[]

- December 2022: Making briquettes - Congolese AfriShiners member Guillain Maliyamungu Nabahya provided a link to a video on local TV broadcast about briquette making. Enjoy the show by clicking on the following link: Briquette manufacturing. AfriShiners member Millicent Anyango from Rongo, Migori County, Kenya, is proceeding the same way with her briquette production.

- August 2015: The Mount Kenya Energy Project's German organisation Lernen-Helfen-Leben e.V. has focused on the construction of gasifier/pyrolysis stoves during the past three years. These stoves perform very well when pellets or Biomass briquettes made from plant waste are used. MKICDO board members came to the conclusion that making briquettes for sale could be a viable income-generating project for the Kiini workshop. It would also be in line with plans to build gasifier stoves at the new institute and train promotors to market them. Mugo found a young entrepreneur who already had some experiences in setting up such projects. We met and came up with a basic outline for a medium-scale business. The briquettes will be made of sawdust and coffee husks. Sawdust is readily available from carpentry workshops. The husks are a waste product at coffee dry mills and are sold very cheaply. Arrangements were made at a nearby coffee cooperative to be given priority for sales.

Diagram showing the role the solar dryer plays in helping produce dried fruits, vegetables, and briquettes for fuel-efficient cookstoves.

- December 2014: Joshua Guinto, a specialist with Appropriate Technologies has provided an update on recovery developments in the Philippines in the wake of typhoon Haiyan. Their focus has been providing solar dryers to dry fruits and vegetables, as wells to dry wood for bio-char and briquette production for use in fuel-efficient cookstoves. Read more at: The Approtech Training for Salcedo Eastern Samar - Joshua Guinto, November 2014

Constructions plans[]

Variations[]

Honeycomb biomass briquettes[]

Beehive briquettes and the briquettes mold (ICIMOD, 2009)

Briquettes make use of compacted agricultural wastes, including fallen dry leaves, for fuel. Beehive briquettes (a honeycomb beehive-shaped biomass briquette) are made using a hand mould. The air channels help the briquette burn more easily.

Resources[]

Reports[]

- January 2013: Solar Cooking with Integrated Systems - FOST

Audio and video[]

- May 2018:

FoST Lapu EN-0

FoST demonstrates production of briquettes in Lapu Village in Nepal.

- April 2016: Video of a project in Mauritania showing how an invasive plant can be used to make charcoal briquettes (French)

- October 2013:

- June 2010:

NGOs using biomass briquettes[]

External links[]

- Open Source DIY Biomass Briquette Technology Design and Formulations

- Make a biomass processor - Engineering for Change

- Partnership for Clean Indoor Air (PCIA) Bulletin #29 The issue focuses on the fuel side of the improved stoves equation, with an in depth discussion of charcoal and briquettes.

- HELVETAS Swiss Intercooperation document containing information about their biomass briquette work